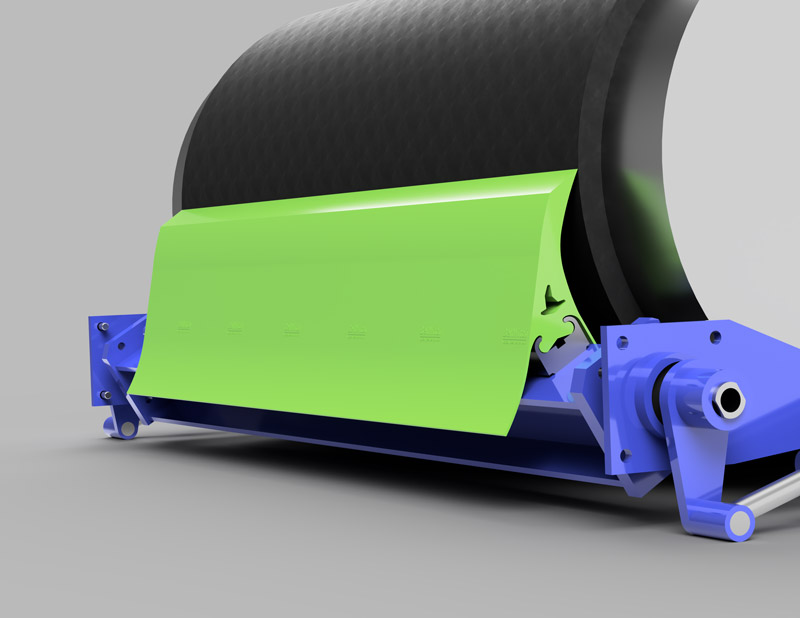

A good scraper design is essential for an efficient solution to remove effectively carry back from the belt surface. Our primary scraper are developed in the harsh conditions of the large German surface mines. Based on a special Polyurethane mixture reduced wear and belt protection stood in the main focus of the development. The unique WitchHead suspension system offers to evade in case of a belt damage without harming the scraper or the belt conveyor. The contact pressure is given by the BeltWitch Hybrid AirSpring, a combination of the pneumatic scraper und ingenious backup system. The desired contact pressure is given for many months also without any air supply. A system which is nearly maintenance free.

BeltWitch® Primary Scraper

Advantages of the Primary Scraper:

- Durable solid Polyurethane mixture for ultra long lifetime

- Unique BeltWitch suspension system

- Innovative, new hybrid air spring for optimzed pressure distribution on the blade

- BeltWitch Quick Relase system for easy exchange of the blade

- Solid, heavy duty frame construction

Technical Specifications

- Available for Conveyor width between 600 and 2800mm

- Hybrid Air Spring

- Durable heavy-duty design

Get In Touch

The fields marked with * are required

- Address RECA Plastics GmbH

Zaunheimer Str. 22

56072 Koblenz - E-Mailinfo@reca-plastics.com

- Phone+49 (0) 261 - 988 17 - 0

+49 (0) 261 - 988 17 - 729